As a global core base for in-vehicle cameras, image sensor modules, and ETC in-vehicle equipment, the Shirakawa Plant takes the lead in manufacturing collaborations with plants in China and Mexico. We interviewed a young employee who is aiming for growth by passing on technology.

Our new generation wireless charger was installed as standard equipment in all grades of the fully remodeled Toyota’s new Alphard/Vellfire. What challenges did you face in ? We spoke with employees from the development and sales divisions.

The Japan Automotive AI Challenge is an international competition for AI technologies related to automated driving, with the aim of discovering and fostering engineers who will lead the automotive industry in the future. This section introduces the activities of our young engineers who are aiming to win this competition.

Attracting 230,000 visitors over three days, Tokyo Auto Salon 2024 in Japan was the world’s largest custom car event. The event saw car manufacturers from around the world propose the future of cars while unique car stores competed in tuning and customization, filling the venue with the energy of car enthusiasts.

Our 48-inch rear-seat display system (48-inch display) has been adopted by Toyota Motor Corporation (hereinafter Toyota) for its Lexus LM. We interviewed the engineer who focused his energy on site to learn about his development journey and the difficulties he faced.

Nissan Motor Corporation (hereinafter Nissan) has adopted our drive recorder–linked electronic mirror system for its Serena. This is the first time Nissan has adopted our drive recorder–linked electronic mirror system. Instead of being complacent about the stable adoption of electronic mirrors, we believed that aggressively proposing innovations was the only way to survive.

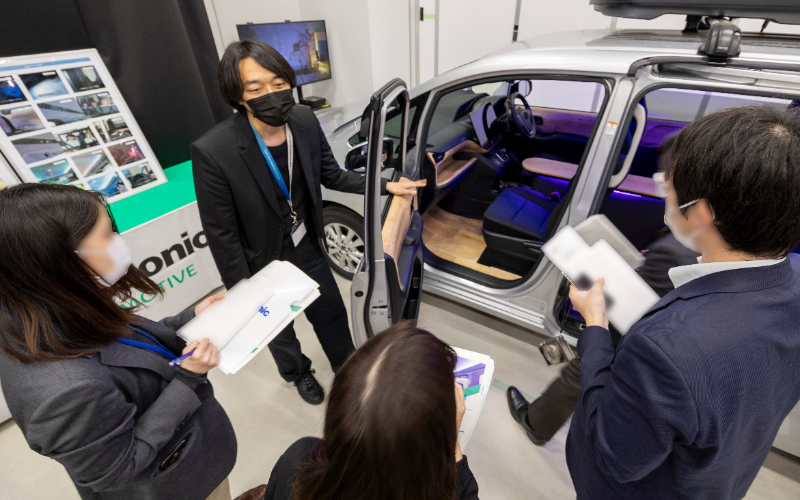

Panasonic Automotive Systems Co., Ltd. exhibited at CEATEC 2023, Asia’s largest general electronics exhibition, which opened on October 17. In collaboration with Panasonic Group business companies, we exhibited Automotive Devices & Solutions that present an extensive range of in-vehicle devices and innovations in an easy-to-understand and intuitive manner to visitors.

This section introduces the activities of the Kusatsu Factory of the Energy Management Systems Business Unit, Automotive Systems Business Division, a manufacturing site where energy conservation activities are in full swing. Major production items include heaters that warm car seats and steering wheels, EV charging cables, and electric compressors, which are the focus of energy-saving activities.

Panasonic Automotive has begun to shift its business model from responding to requests from car manufacturers to proposing innovations directly to car manufacturers. This article introduces the team of marketing, technology, and design professionals spearheading this transition.

Against the backdrop of the development of CASE (Connected, Automated driving, Sharing, and Electrification), the burden of car development is increasing like never before. Panasonic Automotive Systems Co., Ltd. has established a new software development process through co-creation with Mazda Motor Corporation. The technology is being used in the development of a drive recorder control function for the MAZDA CX-60 connectivity master unit for the domestic market, which went on sale in Japan this fall.