Innovation

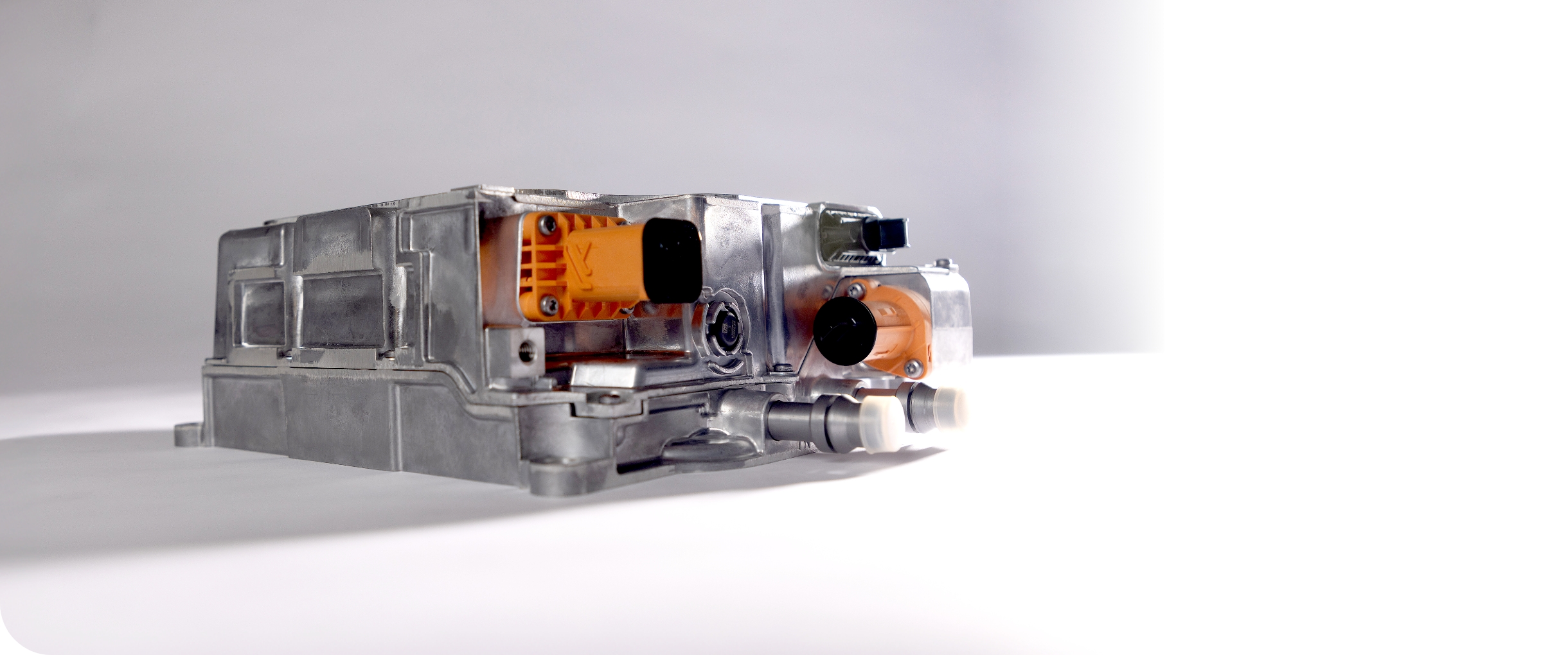

EV Power Electronics (On-Board Charger)

Contribute to the Reduction of CO2 Emissions through the Pursuit of Power Conversion Technology

With the expanding popularity of Electric Vehicles (EVs), On-Board Chargers (OBCs) have become the standard and are an important system that reduces power consumption, and especially CO2 emissions, during charging.

In 2012, we were the first company in the industry to supply Nissan Motor Corporation with an On-Board Charger system (*1), which is now the mainstream system. In 2020, as an evolution of our power conversion technology, we delivered an Integrated System (*2) to European automobile manufacturers that is even more downsized, more highly efficient technology, and higher output.

Currently, we still have the industry’s top level of power conversion efficiency in high-power On-Board-Chargers (“Power Conversion Efficiency” is one of the most important factors in the performance of On-Board Chargers), and our customers have high expectations for our products in terms of shorter charging times, improved efficiency, and further downsizing.

We are working on technological innovations such as further downsizing, higher output/voltage, and effective utilization of clean energy (bi-directional), etc. As part of these efforts, we have won the project contract offered by Ministry of the Environment in cooperation with Nagoya University.

- A system product that integrates the charging function and a DC/DC converter (converts DC to DC and converts or stabilizes it to the required voltage).

- An integrated system that integrates an OBC with a DC/DC converter that reduces and supplies power to the entire vehicle system from a high-output OBC or automotive batteries.

Highest Level Power Conversion Efficiency in the Industry

Reduction of Electricity Consumption Along with EV Popularization Contributes Significantly to CO2 Reduction

Since the drive motors and other components of BEV run on direct current (DC) and high voltage, it is necessary to convert alternating current (AC) to DC using an On-Board Charger (hereinafter referred to as OBC) when charging automotive batteries from a 100V or 200V AC power supply used at homes, etc.

During this process, recharging losses generally occur in proportion to the power conversion efficiency. The power conversion efficiency of our mass produced products is already as high as 96%, and we aim to achieve the highest level of 98% in the industry by 2030 through further technological innovation.

Improved power conversion efficiency helps to reduce CO2 emissions as well. If the power conversion efficiency is improved by 3% and this technology is applied to EVs worldwide, CO2 emissions can be reduced by 7.54 million tons※. Generally speaking, each household emits 5,600kg of CO2 per year, and it is said that it takes about 600 cedar trees to absorb this amount of CO2, so the CO2 reduction effect of EV popularization is significant.

- Electricity consumption by EVs in 2030 is estimated to be 555 TWh/year.

Focus on the High Output and High Voltage Areas and Contribute to Shorter Charging Times

Besides power conversion efficiency, another factor related to OBC performance is output voltage, and the higher the output voltage value, the faster the charging can be performed. For example, the output of OBCs being developed as of 2023 ranges from 3.3 kW to 22 kW. When using normal charging from an AC power source at home, the charging time can be reduced to 1/6 or less by a simple calculation.

On the other hand, the designing OBCs that can handle high output requires advanced technological capabilities to solve insulation, EMC (electromagnetic compatibility), thermal issues, and more, and there are not many automotive component manufacturers globally that can meet these requirements.

We have achieved high output through prior mass production experience and original technological innovations. In the future, we will help reduce charging times by increasing output power, including downsizing devices and making them more efficient, in order to support charging systems with battery voltages of 800V, which is expected to become more popular globally.

Won the Project Contract by the Ministry of the Environment to Improve Conversion Efficiency.

Develop Technology in Collaboration with Nagoya University

A key technology that will bring further innovation in improving conversion efficiency and shortening charging times to OBCs is the application of wide band gap power semiconductors based on gallium nitride (GaN), which offer high voltage, high frequency drive, and low loss. Joint development of advanced technology will be conducted in collaboration with Nagoya University under the theme of Technological Development of High-Performance On-Board Charging System for EVs Using Wide Band Gap Semiconductors as part of the Ministry of the Environment’s FY2023 Technology Development and Demonstration Project for Regional Symbiosis and Cross-Sectoral Carbon Neutrality.

<Reference>

Technological Development of High-Performance On-board Charging System for BEVs Using Wide Band Gap Semiconductors (Japanese)

https://www.env.go.jp/earth/ondanka/cpttv_funds/db_current/

Contribute to CO2 Reduction through EV Power Electronics and Technological Innovation

In order to meet the expectations of our customers, we launched our OBC on the market in 2012 and have accumulated mass production experience, technology, and knowledge. We will continue to pursue further technological development of EV power electronics (higher efficiency, higher output, higher voltage, and bi-directional) in order to conserve the global environment by helping to electrify vehicles.